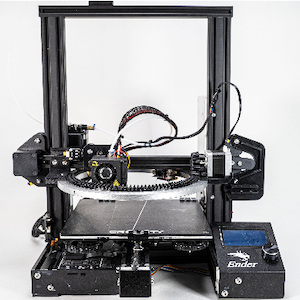

We introduce Rhapso, a 3D printing system designed to embed a diverse range of continuous fiber materials within 3D objects during the printing process. This approach enables integrating properties like tensile strength, force storage and transmission, or aesthetic and tactile characteristics, directly into low-cost thermoplastic 3D prints. These functional objects can have intricate actuation, self-assembly, and sensing capabilities with little to no manual intervention. To achieve this, we modify a low-cost Fused Filament Fabrication (FFF) 3D printer, adding a stepper motor-controlled fiber spool mechanism on a gear ring above the print bed. In addition to hardware, we provide parsing software for precise fiber placement, which generates G-code for printer operation. To illustrate the versatility of our system, we present applications that showcase its extensive design potential. Additionally, we offer comprehensive documentation and open designs, empowering others to replicate our system and explore its possibilities.