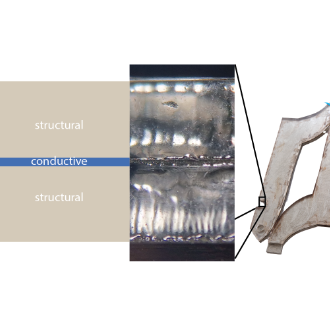

Rapid prototyping is an important tool for designers, but many fabrication techniques are slow and create bulky components requiring multiple machines and processes to achieve desired device shape and electronic functionality. Prior work explored ways to ease fabricating shapes or designing electronics, but we focus on creating shape and electrical pathways at the same time from a single material and machine. LaCir leverages a three-layered, laser-cuttable material to incorporate circuits into the structural substrate of the design using laser cutters. Our substrate features a layer of conductive material sandwiched between thermoplastic sheets, allowing designers to cut electrical traces and assembleable, 3D object geometry in a single pass. We evaluate different composite materials, weighing their cuttability, ease of assembly, and conductivity; we also show using fully laser-cut joints as structural and electrical connections. We demonstrate LaCir's flexibility through several example artifacts.